High Grade Finished Network Cable factory

Benefits of Using High Grade Finished Network Cables in Industrial Settings

In industrial settings, the importance of having a reliable and efficient network infrastructure cannot be overstated. With the increasing reliance on technology and data-driven processes, having a high-quality network cable system is essential for ensuring smooth operations and maximizing productivity. This is where high-grade finished network cables come into play.

High-grade finished network cables are specifically designed to meet the demands of industrial environments. These cables are built to withstand harsh conditions such as extreme temperatures, moisture, and electromagnetic interference. This makes them ideal for use in factories, warehouses, and other industrial settings where reliability is paramount.

One of the key benefits of using high-grade finished network cables in industrial settings is their durability. These cables are constructed using high-quality materials that are designed to last for years, even in the most demanding environments. This means that you can rely on these cables to provide a stable and consistent connection, without having to worry about frequent replacements or downtime.

Another advantage of high-grade finished network cables is their superior performance. These cables are engineered to deliver high-speed data transmission, ensuring that your network operates at peak efficiency. This is crucial in industrial settings where real-time data is essential for monitoring and controlling processes. With high-grade finished network cables, you can trust that your data will be transmitted quickly and accurately, allowing you to make informed decisions and respond to changes in real-time.

In addition to their durability and performance, high-grade finished network cables also offer enhanced security features. These cables are designed to protect against data breaches and cyber attacks, ensuring that your sensitive information remains safe and secure. This is especially important in industrial settings where data security is a top priority. By using high-grade finished network cables, you can rest assured that your network is protected from potential threats and vulnerabilities.

Furthermore, high-grade finished network cables are easy to install and maintain. These cables are designed for quick and hassle-free installation, allowing you to set up your network infrastructure with minimal downtime. Additionally, these cables require little maintenance, saving you time and money in the long run. This means that you can focus on running your operations smoothly, without having to worry about constant upkeep and repairs.

Overall, the benefits of using high-grade finished network cables in industrial settings are clear. From their durability and performance to their security features and ease of installation, these cables offer a reliable and efficient solution for your network infrastructure needs. By investing in high-grade finished network cables, you can ensure that your industrial operations run smoothly and efficiently, allowing you to stay ahead of the competition and achieve your business goals.

How to Choose the Right High Grade Finished Network Cable for Your Business

In today’s digital age, having a reliable network infrastructure is crucial for the success of any business. Whether you are a small startup or a large corporation, having the right high-grade finished network cable is essential for ensuring seamless communication and data transfer within your organization. With so many options available in the market, choosing the right network cable can be a daunting task. However, by understanding the different types of network cables and their specific uses, you can make an informed decision that meets the needs of your business.

When it comes to high-grade finished network cables, there are several factors to consider. The first and most important factor is the type of cable. There are several types of network cables available, including Ethernet cables, fiber optic cables, and coaxial cables. Ethernet cables are the most common type of network cable and are used for connecting devices within a local area network (LAN). Fiber optic cables, on the other hand, are used for long-distance communication and offer higher bandwidth and faster data transfer speeds. Coaxial cables are typically used for cable television and internet connections.

Another important factor to consider when choosing a high-grade finished network cable is the category of the cable. Network cables are categorized based on their performance and data transmission capabilities. The most common categories of network cables are Cat5e, Cat6, and Cat6a. Cat5e cables are suitable for basic networking needs and offer speeds of up to 1 Gbps. Cat6 cables offer higher performance and speeds of up to 10 Gbps, making them ideal for businesses with high data transfer requirements. Cat6a cables are the highest category of network cables and offer speeds of up to 10 Gbps over longer distances.

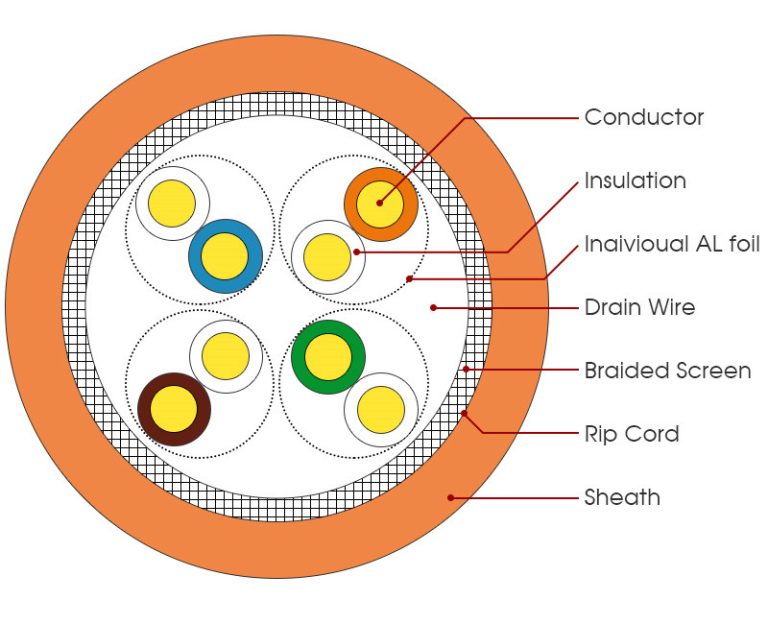

In addition to the type and category of the network cable, it is also important to consider the quality of the cable. High-grade finished network cables are made from high-quality materials that ensure reliable performance and durability. Look for cables that are made from high-grade copper conductors and have a sturdy outer jacket that protects the cable from damage. It is also important to choose cables that are certified by industry standards organizations, such as the Telecommunications Industry Association (TIA) or the International Organization for Standardization (ISO).

When choosing a high-grade finished network cable for your business, it is also important to consider the length of the cable. It is important to choose a cable that is the right length for your networking needs. If the cable is too short, it may not reach all the devices in your network. If the cable is too long, it may result in signal loss and slower data transfer speeds. Measure the distance between your devices and choose a cable that is slightly longer than the distance to ensure a proper fit.

In conclusion, choosing the right high-grade finished network cable for your business is essential for ensuring reliable communication and data transfer within your organization. Consider factors such as the type, category, quality, and length of the cable to make an informed decision that meets the needs of your business. By investing in high-quality network cables, you can ensure that your business operates smoothly and efficiently.

The Importance of Quality Control in High Grade Finished Network Cable Manufacturing

In the world of technology, network cables play a crucial role in ensuring seamless communication and data transfer. As such, the quality of these cables is of utmost importance to ensure reliable and efficient performance. This is where high-grade finished network cable factories come into play.

These factories specialize in the manufacturing of top-quality network cables that meet the highest industry standards. From the selection of raw materials to the final inspection of the finished product, every step in the manufacturing process is carefully monitored to ensure the highest level of quality control.

One of the key aspects of quality control in high-grade finished network cable manufacturing is the selection of raw materials. High-quality network cables are made from premium materials that are durable, flexible, and capable of transmitting data at high speeds. By carefully selecting the right materials, manufacturers can ensure that their cables meet the required specifications and deliver optimal performance.

Once the raw materials are selected, they undergo a series of rigorous tests to ensure their quality and reliability. This includes testing for conductivity, insulation, and durability to ensure that the cables can withstand the rigors of daily use without compromising on performance.

The manufacturing process itself is also closely monitored to ensure that each cable is produced to the highest standards. From the extrusion of the cable jacket to the twisting of the individual wires, every step in the process is carefully controlled to ensure consistency and quality.

Quality control measures are also in place during the assembly and termination of the cables. This includes testing the cables for continuity, signal integrity, and impedance to ensure that they meet the required specifications for data transmission.

Once the cables are assembled, they undergo a final inspection to ensure that they meet the highest quality standards. This includes visual inspection, electrical testing, and performance testing to ensure that the cables are free from defects and capable of delivering reliable performance.

By implementing strict quality control measures throughout the manufacturing process, high-grade finished network cable factories can ensure that their products meet the highest industry standards and deliver optimal performance. This not only helps to build trust and confidence among customers but also ensures that the cables can meet the demands of modern networking applications.

In conclusion, the importance of quality control in high-grade finished network cable manufacturing cannot be overstated. By carefully selecting raw materials, monitoring the manufacturing process, and conducting rigorous testing, manufacturers can ensure that their cables meet the highest standards of quality and reliability. This not only benefits customers by providing them with reliable and efficient network cables but also helps to maintain the reputation of the manufacturer in the industry. Ultimately, quality control is essential for ensuring that high-grade finished network cables can meet the demands of modern networking applications and deliver optimal performance.

| Number | Commodity Name |

| 1 | cable patch cord |