LSZH network cable factory

Benefits of Using LSZH Network Cables in Industrial Settings

In industrial settings, the safety and reliability of network cables are of utmost importance. One type of cable that is gaining popularity in these environments is LSZH (Low Smoke Zero Halogen) network cables. These cables are designed to emit minimal smoke and no toxic halogens when exposed to high temperatures, making them ideal for use in areas where fire safety is a concern.

One of the key benefits of using LSZH network cables in industrial settings is their ability to reduce the risk of fire hazards. In the event of a fire, traditional PVC cables can emit large amounts of smoke and toxic fumes, which can be harmful to both people and equipment. LSZH cables, on the other hand, produce significantly less smoke and do not release toxic halogens, making them a safer choice for industrial environments.

Another advantage of LSZH network cables is their durability and reliability. These cables are designed to withstand harsh conditions, such as extreme temperatures, moisture, and chemicals, making them well-suited for use in industrial settings where environmental factors can be unpredictable. Additionally, LSZH cables are less prone to damage from bending and twisting, ensuring a stable and consistent network connection.

In addition to their safety and reliability, LSZH network cables are also environmentally friendly. The materials used in these cables are non-toxic and recyclable, making them a sustainable choice for businesses looking to reduce their environmental impact. By choosing LSZH cables, industrial facilities can not only improve safety and reliability but also demonstrate their commitment to sustainability.

Furthermore, LSZH network cables are easy to install and maintain, saving time and resources for industrial facilities. These cables are lightweight and flexible, making them easy to work with in tight spaces or complex installations. Additionally, LSZH cables require less frequent maintenance compared to traditional PVC cables, reducing downtime and maintenance costs for businesses.

Overall, the benefits of using LSZH network cables in industrial settings are clear. From improved safety and reliability to environmental sustainability and ease of installation, these cables offer a range of advantages for businesses looking to enhance their network infrastructure. By choosing LSZH cables, industrial facilities can ensure a secure and efficient network connection while also promoting a safer and more sustainable working environment.

In conclusion, LSZH network cables are an excellent choice for industrial settings due to their safety, reliability, environmental sustainability, and ease of installation. By investing in LSZH cables, businesses can enhance their network infrastructure and create a safer and more efficient working environment for employees. With the numerous benefits that LSZH cables offer, it is clear that they are a valuable asset for industrial facilities looking to improve their network connectivity.

How LSZH Network Cables Ensure Safety in Commercial Buildings

In the world of commercial buildings, safety is always a top priority. From fire alarms to emergency exits, every aspect of a building’s infrastructure is designed with safety in mind. One often overlooked component of a building’s safety system is the network cables that run throughout the structure. These cables are essential for providing internet and communication services, but they can also pose a serious safety risk if they are not properly designed and installed.

This is where LSZH network cables come into play. LSZH stands for Low Smoke Zero Halogen, and these cables are specifically designed to minimize the amount of smoke and toxic fumes that are released in the event of a fire. This is crucial in commercial buildings, where large numbers of people may be present and evacuation routes need to remain clear and safe.

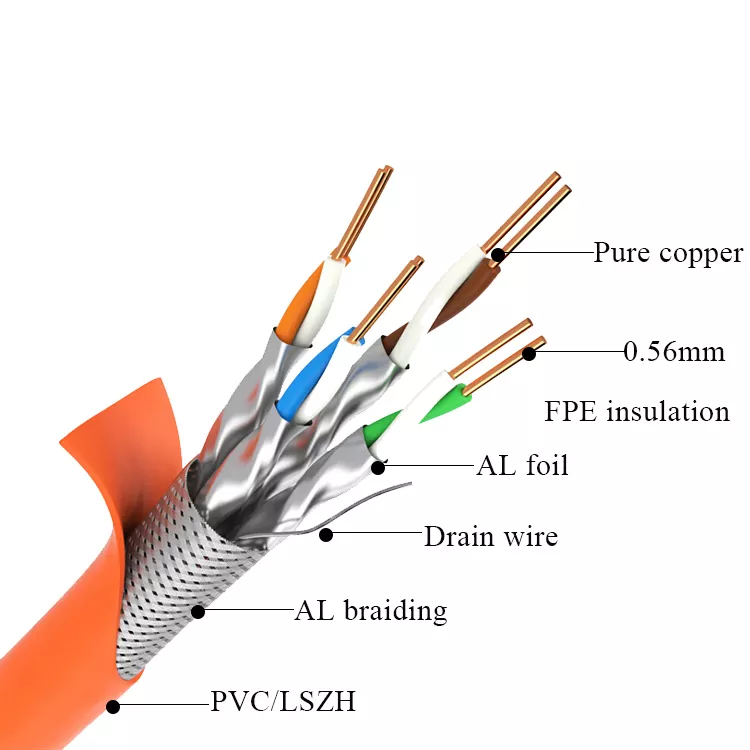

LSZH network cables are made from materials that do not contain halogen compounds, which are known to produce harmful gases when burned. Instead, these cables are made from materials such as polyethylene or polypropylene, which produce minimal smoke and fumes when exposed to fire. This can greatly reduce the risk of smoke inhalation and improve the chances of a safe evacuation in the event of a fire.

In addition to their safety benefits, LSZH network cables are also more environmentally friendly than traditional PVC cables. PVC cables release harmful chemicals when burned, contributing to air pollution and posing a risk to human health. LSZH cables, on the other hand, produce minimal emissions when burned, making them a more sustainable choice for commercial buildings.

When it comes to choosing a network cable for a commercial building, safety should always be the top priority. LSZH cables offer a number of advantages over traditional PVC cables, including improved fire safety, reduced environmental impact, and peace of mind for building occupants. By investing in LSZH cables, building owners can ensure that their infrastructure is as safe and secure as possible.

LSZH network cables are manufactured in specialized factories that adhere to strict quality control standards. These factories use state-of-the-art equipment and processes to produce cables that meet the highest safety and performance standards. From the selection of raw materials to the final testing of the finished product, every step of the manufacturing process is carefully monitored to ensure that LSZH cables are of the highest quality.

| No. | Name |

| 1 | Test network cable via Fluke |

In conclusion, LSZH network cables are an essential component of a safe and secure commercial building. By choosing LSZH cables, building owners can protect their occupants from the dangers of smoke and toxic fumes in the event of a fire. With their superior safety features and environmental benefits, LSZH cables are the smart choice for any commercial building looking to prioritize safety and sustainability.

The Environmental Impact of LSZH Network Cable Production

LSZH network cables, or Low Smoke Zero Halogen cables, are becoming increasingly popular in the telecommunications industry due to their environmentally friendly properties. These cables are made with materials that do not emit toxic fumes when burned, making them safer for both humans and the environment. However, the production of LSZH network cables also has its own environmental impact that needs to be considered.

One of the main environmental concerns with LSZH network cable production is the use of raw materials. The materials used to make LSZH cables, such as polyethylene and polypropylene, are derived from fossil fuels. The extraction and processing of these materials can have a significant impact on the environment, including air and water pollution, habitat destruction, and greenhouse gas emissions.

In addition to the environmental impact of raw material extraction, the manufacturing process of LSZH network cables also contributes to environmental degradation. The production of these cables requires energy-intensive processes, such as extrusion, cabling, and jacketing. These processes often rely on fossil fuels for power, leading to the release of greenhouse gases and other pollutants into the atmosphere.

Furthermore, the disposal of LSZH network cables at the end of their life cycle can also have environmental consequences. While LSZH cables are designed to be more environmentally friendly than traditional PVC cables, they still contain materials that may not be easily recyclable or biodegradable. Improper disposal of these cables can lead to pollution of landfills and waterways, as well as potential harm to wildlife.

Despite these environmental concerns, there are steps that LSZH network cable factories can take to minimize their impact on the environment. One way is to invest in renewable energy sources, such as solar or wind power, to reduce the carbon footprint of the manufacturing process. Additionally, factories can implement more efficient production techniques and recycling programs to reduce waste and conserve resources.

Another important consideration for LSZH network cable factories is the use of eco-friendly materials in cable production. By sourcing materials from sustainable suppliers and using recycled or biodegradable components, factories can reduce their environmental impact and promote a more circular economy.

Overall, the environmental impact of LSZH network cable production is a complex issue that requires careful consideration and proactive measures to mitigate. While these cables offer many benefits in terms of safety and performance, it is important for manufacturers to be mindful of their environmental footprint and work towards more sustainable practices. By taking steps to reduce energy consumption, minimize waste, and use eco-friendly materials, LSZH network cable factories can help protect the environment for future generations.