cable patch cord custom order Sale Factory Direct Price ,Finished Network Cable factory ,Cheapest crossover cable Manufacturer Directly Supply ,cat5e network cable patch or crossover Customization f

Advantages of Ordering Custom Cable Patch Cords Directly from the Factory

In the realm of networking, the efficiency and reliability of cable connections are paramount. Whether it’s for home use or within large-scale commercial settings, the quality of cables can significantly impact data transmission speeds and overall network performance. In recent years, the option to order custom cable patch cords directly from the factory has gained traction among consumers and businesses alike. This article delves into the advantages of opting for this approach.

Firstly, one of the most notable benefits of ordering custom cable patch cords directly from the factory is the ability to tailor them to specific requirements. Unlike off-the-shelf cables that come in standard lengths and configurations, custom orders allow for precise specifications to be met. This level of customization ensures that cables are optimized for the intended application, whether it’s for networking, telecommunications, or audio-visual setups.

Moreover, ordering directly from the factory eliminates the middleman, resulting in cost savings for consumers. By bypassing distributors or retailers, customers can access factory-direct prices, which are often more competitive. This direct-to-consumer model cuts down on additional expenses associated with markup and distribution, ultimately offering better value for money.

Another advantage is the assurance of quality control. When purchasing custom cable patch cords from a reputable factory, customers can expect rigorous quality assurance processes to be in place. From the selection of premium materials to thorough testing procedures, manufacturers prioritize product excellence to uphold their reputation. This commitment to quality translates to reliable cables that meet industry standards and exceed performance expectations.

Furthermore, ordering custom cables directly from the factory can lead to shorter lead times. With streamlined production processes and efficient supply chains, factories are equipped to fulfill orders promptly. This is particularly advantageous for businesses with time-sensitive projects or urgent networking needs. By reducing waiting times, customers can expedite their deployment timelines and minimize disruptions to operations.

In addition to standard cable configurations, factory-direct orders often offer the flexibility to create bespoke solutions. Whether it’s custom lengths, unique connectors, or specialized jacketing, manufacturers can accommodate specific requests to meet diverse application requirements. This versatility enables customers to address unique challenges or integrate cables seamlessly into existing infrastructure.

Moreover, ordering directly from the factory fosters direct communication channels between customers and manufacturers. This open dialogue facilitates collaboration and ensures that expectations are clearly communicated and met. Whether it’s seeking technical advice, requesting customizations, or addressing concerns, customers can engage directly with the experts behind the products, fostering trust and accountability.

Lastly, ordering custom cable patch cords directly from the factory can contribute to sustainability efforts. By reducing the reliance on mass-produced, standardized cables, customers can minimize waste and environmental impact. Factory-direct orders enable efficient use of resources by producing cables in quantities tailored to actual demand, rather than excess inventory destined for shelves.

In conclusion, the advantages of ordering custom cable patch cords directly from the factory are manifold. From tailored specifications and cost savings to quality assurance and sustainability, this approach offers a compelling proposition for consumers and businesses seeking reliable networking solutions. By leveraging the expertise and efficiency of manufacturers, customers can unlock a host of benefits that enhance their connectivity infrastructure.

Exploring the Process of Producing Finished Network Cables in a Factory Setting

In the world of networking, the importance of reliable and efficient cables cannot be overstated. Whether it’s for a small home network or a large-scale corporate infrastructure, the quality of cables plays a pivotal role in ensuring smooth data transmission. Amidst the plethora of options available in the market, custom-ordering cables tailored to specific needs has emerged as a popular choice for many consumers. This article delves into the intricate process of producing finished network cables in a factory setting, highlighting the meticulous steps involved in crafting cables that meet individual requirements.

The journey of producing custom network cables begins with understanding the unique needs of the customer. Whether it’s the length of the cable, the type of connectors required, or the specific technical specifications, thorough communication between the customer and the manufacturer lays the foundation for a successful customization process. This initial phase sets the stage for a tailored approach, ensuring that the final product aligns perfectly with the customer’s expectations.

| No. | Commodity Name |

| 1 | patch cable wires |

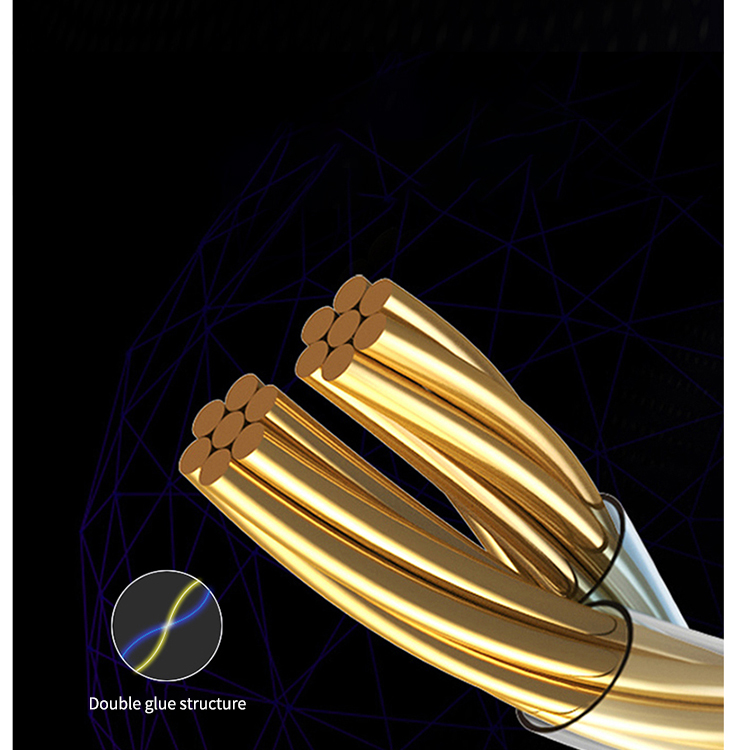

Once the requirements are defined, the manufacturing process kicks off with the selection of high-quality raw materials. From the copper conductors to the outer insulation, every component is carefully chosen to meet industry standards and deliver optimal performance. Manufacturers often maintain stringent quality control measures to ensure that each batch of materials meets the required specifications, thereby guaranteeing the reliability and durability of the finished cables.

With the raw materials in hand, skilled technicians take over to assemble the cables according to the specified configuration. This involves precise cutting, stripping, and crimping of the conductors, followed by meticulous termination of connectors. Whether it’s a standard Ethernet cable or a specialized crossover cable, attention to detail is paramount at every step of the assembly process to ensure consistent quality across all products.

Quality assurance forms an integral part of the manufacturing process, with rigorous testing procedures employed to validate the performance of each cable. From continuity checks to signal integrity tests, every cable undergoes comprehensive evaluation to detect any potential defects or inconsistencies. This commitment to quality control not only safeguards against faulty products but also instills confidence in customers regarding the reliability of the customized cables.

Beyond the technical aspects, manufacturers also prioritize efficiency and scalability in their production processes. By leveraging automation and modern manufacturing techniques, they streamline operations to meet growing demand while maintaining competitive pricing. This emphasis on efficiency not only enhances productivity but also enables manufacturers to offer cost-effective solutions without compromising on quality.

Furthermore, customization extends beyond just the technical specifications of the cables. Manufacturers often provide options for branding and labeling, allowing customers to personalize the cables with their logos or identifiers. This not only adds a professional touch to the finished products but also reinforces brand visibility and recognition.

In conclusion, the process of producing finished network cables in a factory setting is a multifaceted endeavor that demands precision, quality, and customization. From understanding customer requirements to meticulous assembly and testing, every step is orchestrated with care to deliver cables that excel in performance and reliability. By embracing technological advancements and customer-centric approaches, manufacturers continue to push the boundaries of innovation in the realm of network cable customization, catering to the diverse needs of consumers across the globe.

Cost Savings and Quality Assurance: Benefits of Purchasing Crossover Cables Directly from the Manufacturer

In the realm of networking, the importance of quality cables cannot be overstated. Whether for personal or professional use, reliable connectivity is essential for smooth operations and seamless communication. Among the various types of cables available, crossover cables hold a special significance, particularly in facilitating direct connections between similar devices without the need for intermediary equipment like routers or switches. However, sourcing these cables can sometimes be a challenge, with considerations such as cost and quality at the forefront of decision-making processes.

For those seeking cost-effective solutions without compromising on quality, the option of purchasing crossover cables directly from the manufacturer presents a compelling proposition. By bypassing intermediaries and buying straight from the source, businesses and individuals alike stand to benefit from significant cost savings. Manufacturers typically offer competitive factory-direct prices, eliminating markups that often accompany purchases through third-party vendors. This direct purchasing model allows customers to secure high-quality crossover cables at prices that are considerably lower than those found in traditional retail channels.

Moreover, opting to purchase crossover cables directly from the manufacturer offers an added layer of assurance regarding product quality. Manufacturers are inherently invested in upholding their reputation and meeting customer expectations, driving them to maintain stringent quality control measures throughout the production process. This commitment to quality assurance translates into reliable, durable cables that perform optimally in various networking environments. Additionally, manufacturers often provide warranties or guarantees on their products, offering customers peace of mind and protection against potential defects or malfunctions.

Customization is another key advantage afforded by purchasing crossover cables directly from the manufacturer. With the ability to tailor cables to specific requirements, customers can ensure compatibility with their unique networking setups and configurations. Whether it’s selecting the desired length, color-coding for easy identification, or specifying connector types, customization options empower customers to design cables that precisely meet their needs. This level of flexibility is particularly valuable in environments where standard off-the-shelf cables may not suffice, allowing for optimal performance and efficiency.

Furthermore, direct communication with manufacturers enables customers to receive personalized assistance and expert guidance throughout the purchasing process. From initial inquiries to post-sale support, manufacturers are equipped to address any questions or concerns promptly and effectively. This direct line of communication fosters transparency and accountability, ensuring a seamless customer experience from start to finish.

In summary, purchasing crossover cables directly from the manufacturer offers a compelling combination of cost savings and quality assurance. By circumventing intermediaries, customers can secure competitive prices while benefiting from superior product quality, customization options, and personalized support. Whether for businesses looking to optimize their networking infrastructure or individuals seeking reliable connectivity solutions, the advantages of sourcing crossover cables directly from the manufacturer are undeniable. With a focus on delivering value and satisfaction, manufacturers stand as trusted partners in meeting the diverse needs of the networking community.