Cheap Large Electrical Telephone Logarithmic Cable Factory

Exploring Cost-Effective Solutions: A Guide to Establishing a Cheap Large Electrical Telephone Logarithmic Cable Factory

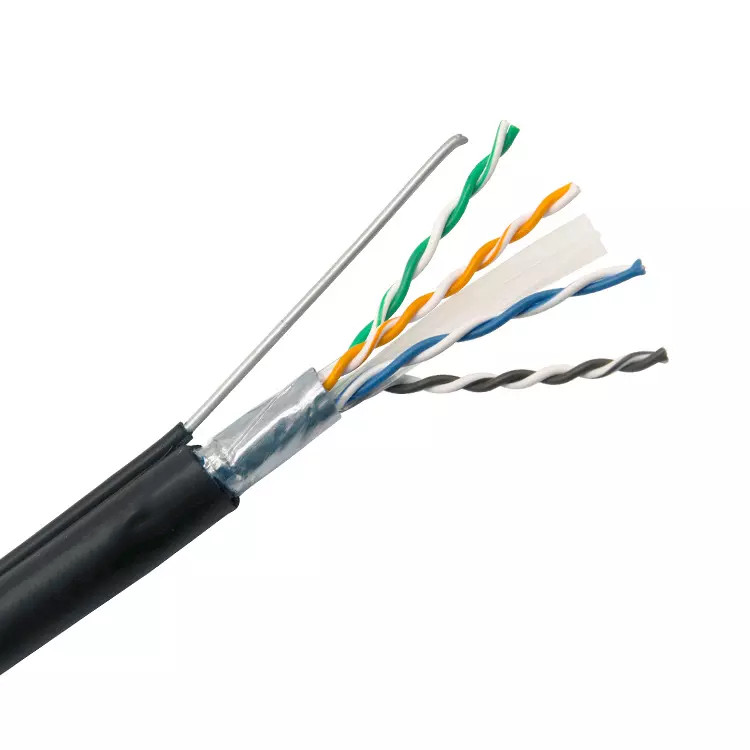

In today’s fast-paced technological landscape, the demand for large electrical telephone logarithmic cables continues to rise. These cables serve as the backbone of communication networks, facilitating the transfer of data and information across vast distances. However, establishing a factory to produce these cables can be a costly endeavor, posing a significant barrier to entry for many aspiring manufacturers.

Fortunately, there are strategies and approaches that can help streamline the process and reduce costs, making it more feasible to establish a cheap large electrical telephone logarithmic cable factory. In this guide, we will explore some of these cost-effective solutions, providing insights and recommendations for entrepreneurs and industry professionals alike.

One of the primary considerations when establishing a cable factory is the selection of materials. Opting for high-quality yet affordable materials is essential for achieving cost savings without compromising on the integrity and performance of the cables. Conducting thorough research and sourcing materials from reliable suppliers can help manufacturers secure competitive prices without sacrificing quality.

| Serial Number | Product Name |

| 1 | Computer LAN Cable |

Additionally, implementing efficient manufacturing processes is key to minimizing production costs. Investing in automation and machinery can significantly increase productivity while reducing labor expenses. By optimizing workflows and streamlining operations, manufacturers can achieve higher output levels with fewer resources, ultimately driving down the overall cost per unit.

Furthermore, embracing innovation and technology can yield substantial cost savings in the long run. Integrating advanced manufacturing techniques such as 3D printing or laser cutting can reduce material waste and enhance precision, resulting in more efficient production processes. Additionally, exploring alternative energy sources, such as solar or wind power, can help offset energy expenses and reduce the factory’s carbon footprint.

Collaborating with other industry players and forming strategic partnerships can also contribute to cost reduction efforts. Pooling resources and sharing infrastructure can lower overhead expenses, while joint research and development initiatives can drive innovation and efficiency across the supply chain. By leveraging collective expertise and resources, manufacturers can achieve economies of scale and improve their competitive position in the market.

Moreover, maintaining a lean and agile organizational structure is essential for cost-effective operations. Eliminating unnecessary bureaucracy and overhead costs can free up resources that can be reinvested into the business or passed on to customers in the form of lower prices. Additionally, fostering a culture of continuous improvement and employee empowerment can enhance productivity and drive cost efficiencies at every level of the organization.

In conclusion, establishing a cheap large electrical telephone logarithmic cable factory requires careful planning, strategic decision-making, and a commitment to cost-effective practices. By selecting the right materials, optimizing manufacturing processes, embracing innovation, fostering collaboration, and maintaining a lean organizational structure, manufacturers can achieve significant cost savings without compromising on quality or performance. With these cost-effective solutions in place, aspiring entrepreneurs can turn their vision of a cable factory into a reality, contributing to the advancement of communication technology and driving economic growth in the process.