Okun Nẹtiwọọki LSZH Didara to gaju Ile-iṣẹ Kannada Kannada

Awọn anfani ti Lilo Awọn okun Nẹtiwọọki LSZH Didara to gaju Ti a ṣelọpọ ni Awọn ile-iṣẹ Kannada

Awọn ẹya ara ẹrọ bọtini lati Wa Nigbati o yan Awọn okun Nẹtiwọọki LSZH lati ọdọ Awọn aṣelọpọ Kannada

Iṣe pataki ti Iṣakoso Didara ni iṣelọpọ Cable Nẹtiwọọki LSZH: Awọn oye lati Awọn ile-iṣẹ Kannada

Nọmba

Orukọ ọja

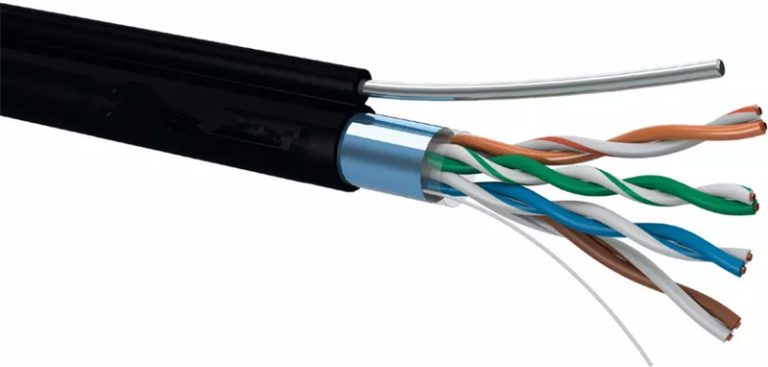

Okun Logarithmic Tẹlifoonu Itanna Tobi

Iṣakoso didara bẹrẹ ni ibẹrẹ ti ilana iṣelọpọ, pẹlu yiyan iṣọra ti awọn ohun elo aise. Awọn ile-iṣelọpọ Ilu Kannada orisun awọn ohun elo didara Ere, ni idaniloju pe awọn paati ti o dara julọ nikan ni a lo ni iṣelọpọ awọn kebulu nẹtiwọọki LSZH. Ifarabalẹ si alaye yii ṣeto ipilẹ fun ọja ipari ti o ga julọ, ti a ṣe afihan nipasẹ agbara, igbẹkẹle, ati iṣẹ.

Ni kete ti wọn ti ra awọn ohun elo aise, wọn ṣe idanwo lile lati rii daju ibamu wọn pẹlu awọn iṣedede ile-iṣẹ. Ipele idanwo iṣaaju-iṣelọpọ ṣe iranlọwọ idanimọ eyikeyi awọn abawọn ti o pọju tabi awọn iyapa, gbigba fun awọn igbese atunṣe lati ṣe imuse ṣaaju ilana iṣelọpọ bẹrẹ. Nipa sisọ awọn ọran ni ipele ibẹrẹ yii, awọn ile-iṣelọpọ Ilu Kannada dinku eewu awọn abawọn ati rii daju didara gbogbogbo ti awọn kebulu ti o pari.

Ilana iṣelọpọ funrararẹ jẹ agbegbe iṣakoso ti o ga pupọ, pẹlu awọn ọna ṣiṣe adaṣe ati ṣiṣe awakọ ẹrọ to ti ni ilọsiwaju ati deede. Awọn onimọ-ẹrọ ti oye ṣe abojuto gbogbo abala ti iṣelọpọ, mimojuto awọn ipilẹ bọtini lati ṣetọju aitasera ati didara jakejado ilana iṣelọpọ. Lati extrusion ati idabobo si fọn ati cabling, kọọkan igbese ti wa ni ṣiṣe pẹlu konge lati pade awọn deede awọn ajohunše ṣeto nipasẹ okeere ilana.

Iṣakoso didara ko ni pari pẹlu awọn Ipari ti awọn ilana; dipo, o gbooro si idanwo igbejade ati ayewo. Awọn ile-iṣelọpọ Ilu Kannada koko-ọrọ gbogbo ipele ti awọn kebulu nẹtiwọọki LSZH si awọn ilana idanwo okeerẹ, pẹlu idanwo iṣẹ ṣiṣe itanna, idanwo aapọn ẹrọ, ati idanwo idaduro ina. Awọn idanwo wọnyi rii daju pe awọn kebulu pade tabi kọja awọn iṣedede ile-iṣẹ fun iṣẹ ṣiṣe, ailewu, ati igbẹkẹle.

Ni afikun si ipade awọn ibeere ilana, awọn ile-iṣẹ Kannada tun ṣe pataki itẹlọrun alabara. Nipa wiwa awọn esi lati ọdọ awọn alabara ati awọn olumulo ipari, wọn tiraka nigbagbogbo lati mu didara ọja dara ati koju eyikeyi awọn ifiyesi tabi awọn ọran ti o le dide. Ọ̀nà oníṣòro oníbàárà yìí ń jẹ́ kí ìgbẹ́kẹ̀lé àti ìdúróṣinṣin jẹ́, ní dídi orúkọ rere àwọn ilé iṣẹ́ Ṣáínà múlẹ̀ gẹ́gẹ́ bí olùpèsè àwọn kebulu nẹtiwọọki LSZH didara ga.

Ni ipari, pataki iṣakoso didara ni iṣelọpọ okun nẹtiwọọki LSZH ko le ṣe apọju. Awọn ile-iṣelọpọ Ilu Kannada ti farahan bi awọn oludari ni aaye yii, mimu awọn imọ-ẹrọ to ti ni ilọsiwaju ṣiṣẹ, awọn iwọn iṣakoso didara lile, ati ifaramo si itẹlọrun alabara lati gbe awọn ọja ti o ga julọ jade. Nipa ifaramọ si awọn iṣedede agbaye ati awọn ilana, awọn ile-iṣelọpọ wọnyi ṣe idaniloju aabo, igbẹkẹle, ati iṣẹ ti awọn kebulu nẹtiwọọki LSZH, ṣiṣe wọn ni yiyan ti o fẹ fun awọn alabara oye agbaye.

| Number | Product Name |

| 1 | Large Electrical Telephone Logarithmic Cable |

Quality control begins at the very inception of the production process, with the careful selection of raw materials. Chinese factories source premium-quality materials, ensuring that only the finest components are used in the manufacturing of LSZH network cables. This attention to detail sets the foundation for a superior end product, characterized by durability, reliability, and performance.

Once the raw materials are procured, they undergo rigorous testing to verify their compliance with industry standards. This pre-production testing phase helps identify any potential flaws or deviations, allowing for corrective measures to be implemented before the manufacturing process commences. By addressing issues at this early stage, Chinese factories minimize the risk of defects and ensure the overall quality of the finished cables.

The manufacturing process itself is a highly controlled environment, with automated systems and advanced machinery driving efficiency and precision. Skilled technicians oversee every aspect of production, monitoring key parameters to maintain consistency and quality throughout the manufacturing process. From extrusion and insulation to twisting and cabling, each step is executed with precision to meet the exacting standards set forth by international regulatory bodies.

Quality control doesn’t end with the completion of the manufacturing process; rather, it extends to post-production testing and inspection. Chinese factories subject every batch of LSZH network cables to comprehensive testing procedures, including electrical performance testing, mechanical stress testing, and flame retardancy testing. These tests ensure that the cables meet or exceed industry standards for performance, safety, and reliability.

In addition to meeting regulatory requirements, Chinese factories also prioritize customer satisfaction. By soliciting feedback from clients and end-users, they continuously strive to improve product quality and address any concerns or issues that may arise. This customer-centric approach fosters trust and loyalty, solidifying the reputation of Chinese factories as providers of high-quality LSZH network cables.

In conclusion, the importance of quality control in LSZH network cable production cannot be overstated. Chinese factories have emerged as leaders in this field, leveraging advanced technologies, stringent quality control measures, and a commitment to customer satisfaction to produce superior products. By adhering to international standards and regulations, these factories ensure the safety, reliability, and performance of LSZH network cables, making them the preferred choice for discerning customers worldwide.